Products

Land-Based-Products

Breather valve

Pressure and vacuum relief breather valve is designed to protect low pressure storage tanks from excessive Pressure (or vacuum) created by thermal expansion (and contraction) and product movement into(out of) the tank and at the same time minizing costly product evaporation/loss.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

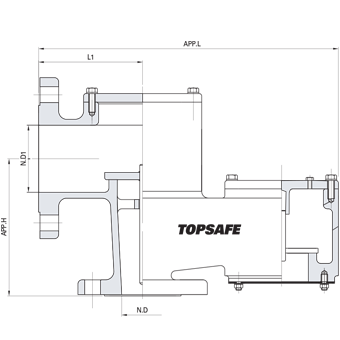

The model KSBG pressure vacuum valves are an advanced design for pipe away applications.

Designed manufactured and tested according to the API2000 code, these valves utilize the latest technologies to provide protection against positive or vacuum over pressure and prevent air intake, evaporative losses of product and help to contain odorous and potentially explosive vapours.

Designed manufactured and tested according to the API2000 code, these valves utilize the latest technologies to provide protection against positive or vacuum over pressure and prevent air intake, evaporative losses of product and help to contain odorous and potentially explosive vapours.

INTRODUCTION

These pressure vacuum valves maintain a tight seal until system pressure or vacuum exceeds the set pressure.

The valves allow an intake of air under constant pressure during emptying, or discharge excessive over pressure during filling of the tanks.

The KSBG is a weight pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of +/- 700mmW.C

High strength, one-body casting provide added structural integrity and durability.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 300mm with ANSI 150lb FF flanges as standard. (Different connections available on request).

The valves allow an intake of air under constant pressure during emptying, or discharge excessive over pressure during filling of the tanks.

The KSBG is a weight pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of +/- 700mmW.C

High strength, one-body casting provide added structural integrity and durability.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 300mm with ANSI 150lb FF flanges as standard. (Different connections available on request).

| PIPE AWAY (WEIGHT TYPE) | |

|---|---|

| SIZE | 2” through 12” |

| MATERIAL | AL / C.S / S.S |

| SETTING PRESSURE | 25 ~ 700mmW.C |

| SETTING VACUUM | -25 ~ -700mmW.C |