Products

Land-Based-Products

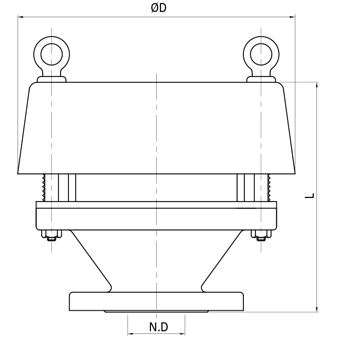

Breather valve

Pressure and vacuum relief breather valve is designed to protect low pressure storage tanks from excessive Pressure (or vacuum) created by thermal expansion (and contraction) and product movement into(out of) the tank and at the same time minizing costly product evaporation/loss.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

Benefits

• Meet USCG, IMO MSC/Circ,677 & EN ISO 16852 requirements

• Designed for Explosion proof

• Maximum Capacity & Minimum Pressure drop

• Quick & Easy removable element

• Very easy cleaning & maintenance

• Vertical installation

• High quality corrosion & chemical resistance

• Meet USCG, IMO MSC/Circ,677 & EN ISO 16852 requirements

• Designed for Explosion proof

• Maximum Capacity & Minimum Pressure drop

• Quick & Easy removable element

• Very easy cleaning & maintenance

• Vertical installation

• High quality corrosion & chemical resistance

INTRODUCTION

The KSFE flame arrester are designed, manufactured and tested according to BS 7244 (British Standard Specification) code and EN ISO 16852.

The units allow free venting in combination with flame protection for vertical vent application.

Housing construction are Aluminum, Cast Iron, Cast Steel, 304SS and 316LSS.

Size are from 20mm through to 300mm.

Cast iron and cast steel units are epoxy coated both inside and outside.

The Flame Arrester of Model KSFE is designed, manufactured, tested according to BS 7244 and EN ISO 16852.

Installed in the end of nozzle of the several kinds of the flammable low pressure storage tank (the ignition point below 65 deg C) with easy coupling, it is the explosion proof and deflagration proof which blocks the influx of flame ignited externally into the tank.

The units allow free venting in combination with flame protection for vertical vent application.

Housing construction are Aluminum, Cast Iron, Cast Steel, 304SS and 316LSS.

Size are from 20mm through to 300mm.

Cast iron and cast steel units are epoxy coated both inside and outside.

The Flame Arrester of Model KSFE is designed, manufactured, tested according to BS 7244 and EN ISO 16852.

Installed in the end of nozzle of the several kinds of the flammable low pressure storage tank (the ignition point below 65 deg C) with easy coupling, it is the explosion proof and deflagration proof which blocks the influx of flame ignited externally into the tank.

| DEFLAGRATION PROOF TYPE | |

|---|---|

| MATERIAL | AL / C.S / S.S |

| SIZE | 2 |

| GAS GROUP | IIA, IIB |