Products

Land-Based-Products

Breather valve

Pressure and vacuum relief breather valve is designed to protect low pressure storage tanks from excessive Pressure (or vacuum) created by thermal expansion (and contraction) and product movement into(out of) the tank and at the same time minizing costly product evaporation/loss.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

Excesses in pressure or vacuum may also cause permanent deformation to the tank or unbalance a vapor recovery system.

The pressure and vacuum relief breather valve is installed on the storage tank roof. The valve may be mounted in onjunction with a KSFH or KSFI flame arrester to provide maximum protection against excessive pressure and vacuum while minizing accidental ignition of flammable product vapor from external sources.

Benefits

• Meet USCG, IMO MSC/Circ,677 & EN ISO 16852 requirements

• Designed for Explosion & Deflagration proof

• Maximum Capacity & Minimum Pressure drop

• Capability of Bi-directional flow & flame arresting

• Quick & Easy removable element

• Very easy cleaning & maintenance

• Available vertical & horizontal installation

• High quality corrosion & chemical resistance

• Useful for vapor mixed line

• Meet USCG, IMO MSC/Circ,677 & EN ISO 16852 requirements

• Designed for Explosion & Deflagration proof

• Maximum Capacity & Minimum Pressure drop

• Capability of Bi-directional flow & flame arresting

• Quick & Easy removable element

• Very easy cleaning & maintenance

• Available vertical & horizontal installation

• High quality corrosion & chemical resistance

• Useful for vapor mixed line

INTRODUCTION

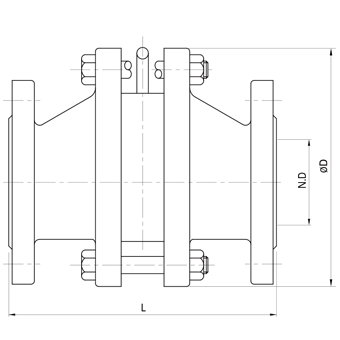

The model KSFL inline flame arrester is designed, manufactured and tested according to API2000 and British Standard Specification Code BS 7244 and EN ISO 16852.

The unit are passive devices with no moving parts.

The KSFL deflagration flame arresters provide protection against flame propagation in piping systems that are manifolded or have long runs.

The arresters are designed to stop an ignited flammable vapor mixture travelling at subsonic vapor velocities.

They are also designed to protect against continuous burning against the 316LSS flame cell for a specific period.

The atandard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

The unit are passive devices with no moving parts.

The KSFL deflagration flame arresters provide protection against flame propagation in piping systems that are manifolded or have long runs.

The arresters are designed to stop an ignited flammable vapor mixture travelling at subsonic vapor velocities.

They are also designed to protect against continuous burning against the 316LSS flame cell for a specific period.

The atandard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

| DEFLAGRATION & EXPLOSION PROOF TYPE | |

|---|---|

| MATERIAL | AL / C.S / S.S |

| SIZE | 2 |

| GAS GROUP | IIA, IIB |