Products

Land-Based-Products

Emergency Vent Cover

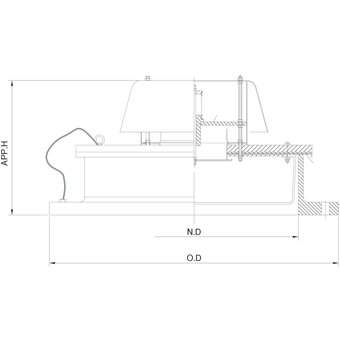

Model KSEP Emergency Vent and manhole cover opens to greatly increase the venting capacity of petroleum storage tanks when the internal pressure rises above the setpoint.

It remains closed tightly at all internal pressure below the settings. This unit also provides easy access into the tank the most common source of this internal pressure is fire exposure.

Type KSEP provides emergency pressure relief only.

The vessel's breather valve must supply vacuum relief requirement.

The type KSEV is the same as the KSEP and in addition offers a spring loaded vacuum relief valve as an integral part of emergency pressure relief cover assembly.

It remains closed tightly at all internal pressure below the settings. This unit also provides easy access into the tank the most common source of this internal pressure is fire exposure.

Type KSEP provides emergency pressure relief only.

The vessel's breather valve must supply vacuum relief requirement.

The type KSEV is the same as the KSEP and in addition offers a spring loaded vacuum relief valve as an integral part of emergency pressure relief cover assembly.

According to API 2000,NFPA 30,ISO 28300 Code.

The series KSEV is designed to provide emergency pressure vacuum relief for storage tanks when exposed to overpressures and overvacuum that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when

properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

The series KSEV is designed to provide emergency pressure vacuum relief for storage tanks when exposed to overpressures and overvacuum that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when

properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

Vent Operation

The KSEV emergency pressure relief vent provides pressure vacuum relief.

When excessive pressure builds within the storage tank the KSEV series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

When excessive pressure builds within the storage tank the KSEV series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction

The series KSEV is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined pressure / vacuum setting range is from a minimum of 25/-25mmW.C to a maximum of 700/-700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.

See Standard material of construction table for available material.

Predetermined pressure / vacuum setting range is from a minimum of 25/-25mmW.C to a maximum of 700/-700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.

| EMERGENCY PRESSURE VACUUM RELIEF MANHOLE(WEIGHT TYPE | |

|---|---|

| SIZE | 16 |

| MATERIAL | AL / C.S / S.S |

| SETTING PRESSURE | 150 ~ 700mmW.C |

| SETTING VACUUM | -150 ~ -700mmW.C |